Mehr als 20 Jahre Erfahrung

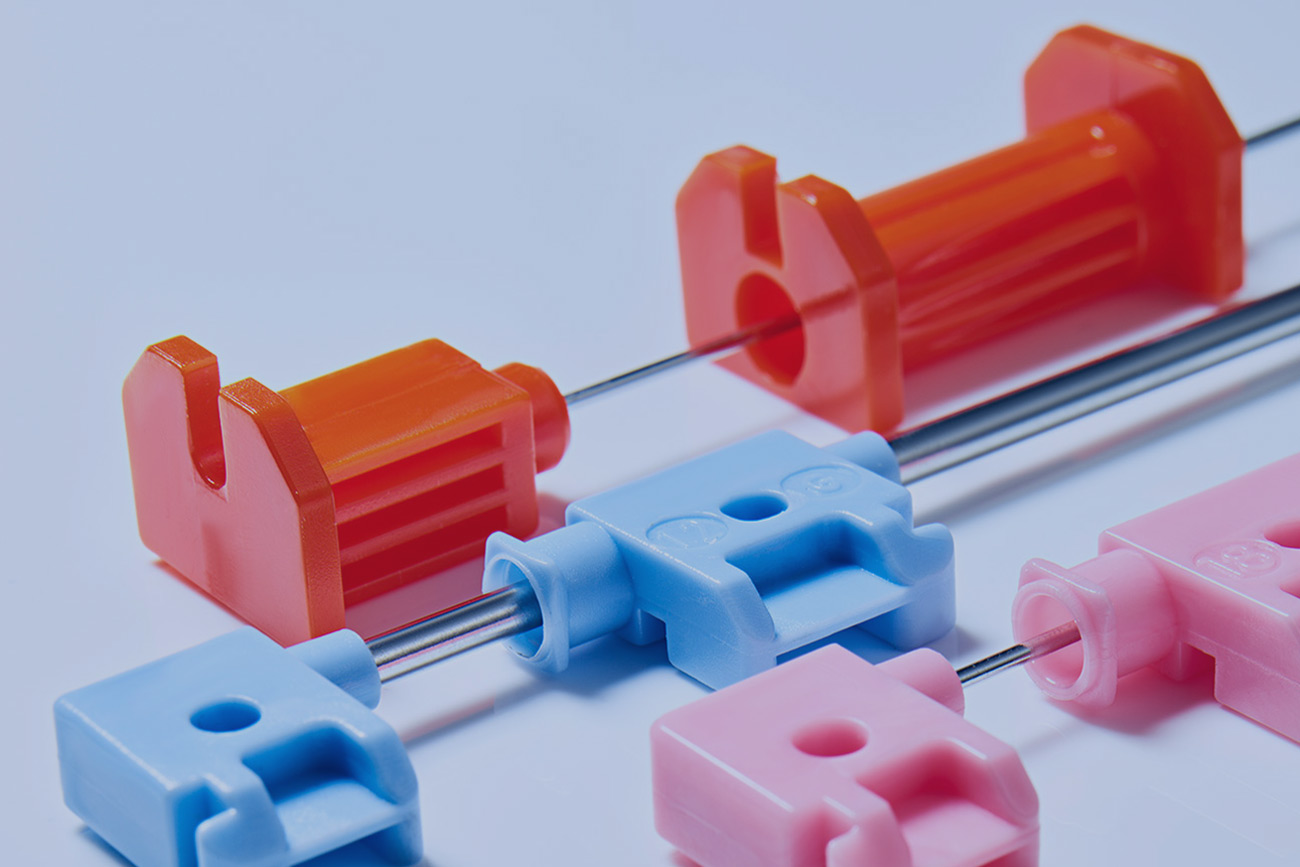

Kunststoffbaugruppen

für die Medizintechnik

Polymold ist ein inhabergeführtes Unternehmen aus dem Bereich Kunststoff-Spritzguss und Werkzeugbau. Unser Fokus liegt auf effizienten Lösungen für Kunden aus der Medizintechnik.

Seit 1999 fertigen wir hochwertige Kunststoffteile und -baugruppen. Dabei sind wir Ihr verlässlicher Partner für die gesamte Prozesskette – von der Entwicklungsbegleitung über den Werkzeugbau bis hin zur Serienproduktion und Montage.

Aktuelles

Ihr Spezialist für Entwicklung, Optimierung und Veredelung

Technisches „Sparring-Gespräch“ mit Gereon Starke vereinbaren

Wie kann ich Ihnen helfen?

Ich bin Ihr Experte (M.Sc. Maschinenbau) für die Produktentwicklung, Optimierung und Oberflächenveredelung. Vereinbaren Sie online einen Termin für ein erstes unverbindliches Gespräch. Ich rufe Sie zum gewünschten Zeitpunkt an. Gemeinsam besprechen wir, wie wir Ihre Vorstellungen und Wünsche optimal umsetzen können.

Reservieren Sie jetzt Ihren Wunschtermin für ein erstes Gespräch!

Gern stehe ich Ihnen auch telefonisch unter +49 8808 92454-29 oder per E-Mail unter entwicklung@polymold.de zur Verfügung.

Ihr Full-Service-Partner

Unsere Leistungen

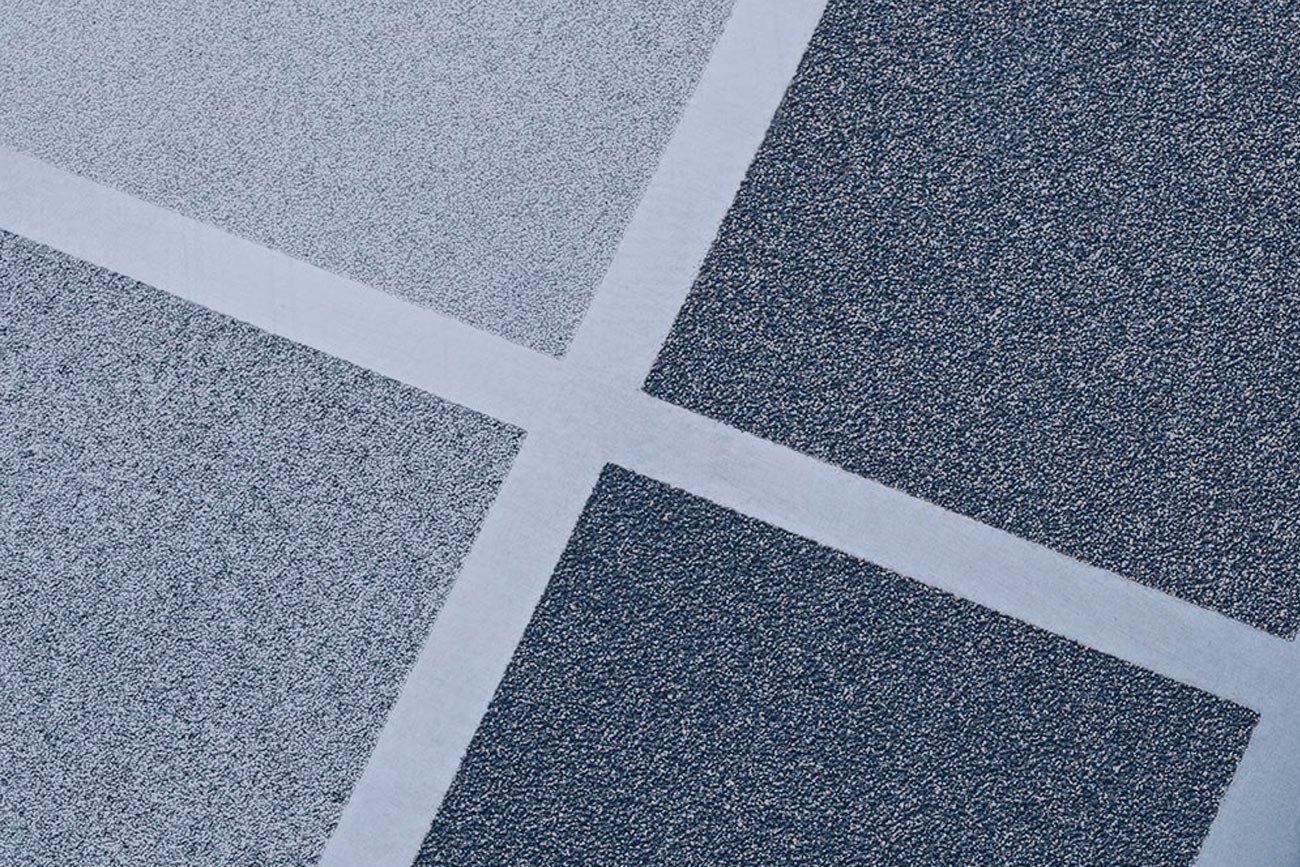

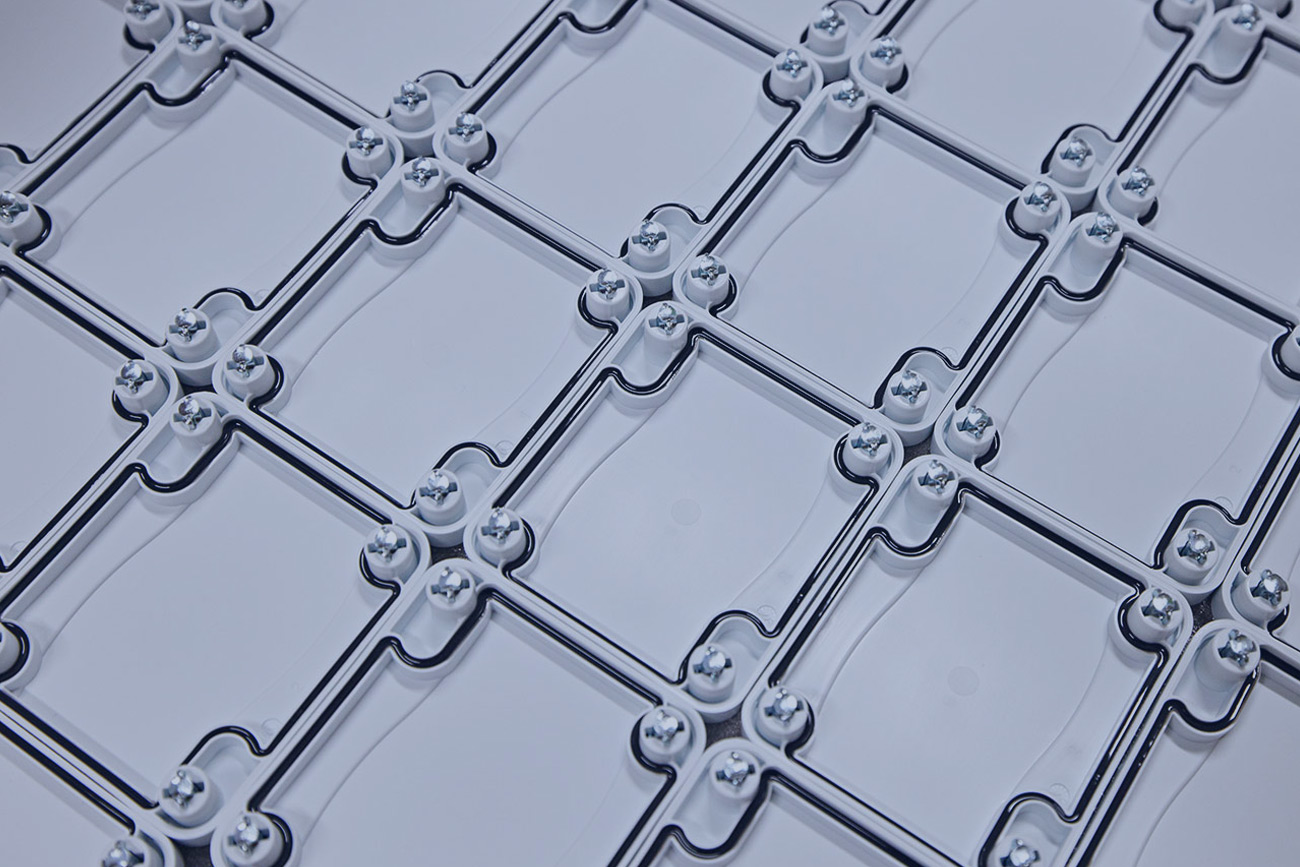

Bei der Herstellung von Kunststoffteilen und -baugruppen begleiten wir Sie durch die gesamte Prozesskette. Wir entwickeln Prototypen, bauen präzise Werkzeuge, produzieren in Serie, veredeln Produkte mittels Lasertexturierung oder Dichtungstechnik und montieren Elemente fachgerecht. Sie erhalten alle Leistungen aus einer Hand.

Ihr Full-Service-Partner

Unsere Leistungen

Bei der Herstellung von Kunststoffteilen begleiten wir Sie durch die gesamte Prozesskette. Wir entwickeln Prototypen, bauen präzise Werkzeuge, produzieren in Serie, veredeln Produkte mittels Lasertexturierung oder Dichtungstechnik und montieren Elemente fachgerecht. Sie erhalten alle Leistungen aus einer Hand.

Ihr Ansprechpartner in der Spritzguss-Produktion

Termin mit Jochen Rührseitz vereinbaren

Wie kann ich Ihnen helfen?

Ich bin Ihr Experte (Diplom-Ingenieur FH Kunststofftechnik) für die Spritzguss-Produktion. Vereinbaren Sie online einen Termin für ein erstes unverbindliches Gespräch. Ich rufe Sie zum gewünschten Zeitpunkt an. Gemeinsam besprechen wir, wie wir Ihre Vorstellungen und Wünsche optimal umsetzen können.

Reservieren Sie jetzt Ihren Wunschtermin für ein erstes Gespräch!

Gern stehe ich Ihnen auch telefonisch unter

+49 8808 92454-22 oder per E-Mail unter projektmanagement@polymold.de zur Verfügung.

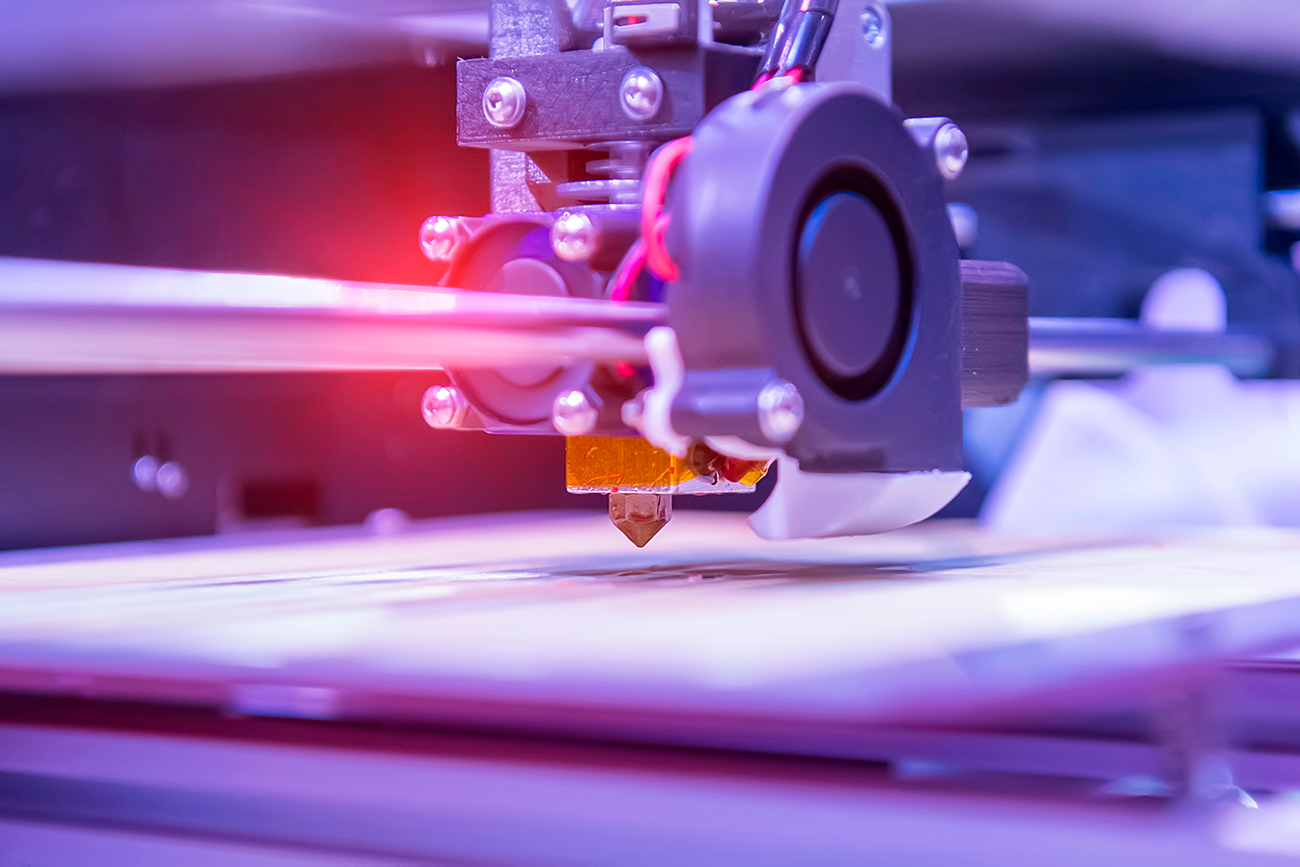

3-D-Prototyping, Texturierung, Optimierung

Know-how für die Entwicklung Ihrer Produkte

Ein umfangreiches Expertenwissen aus der Produktion von Kunststoffteilen und -baugruppen im Spritzgussverfahren steht Ihnen zur Verfügung. Wie lässt sich Ihr Produkt in der von Ihnen gewünschten Form umsetzen? Welche Verbesserungen sind möglich? Wie lässt sich Ihr Produkt effizient in hoher Auflage herstellen? Gemeinsam mit Ihnen entwickelt unser Entwicklerteam das perfekte Produkt.

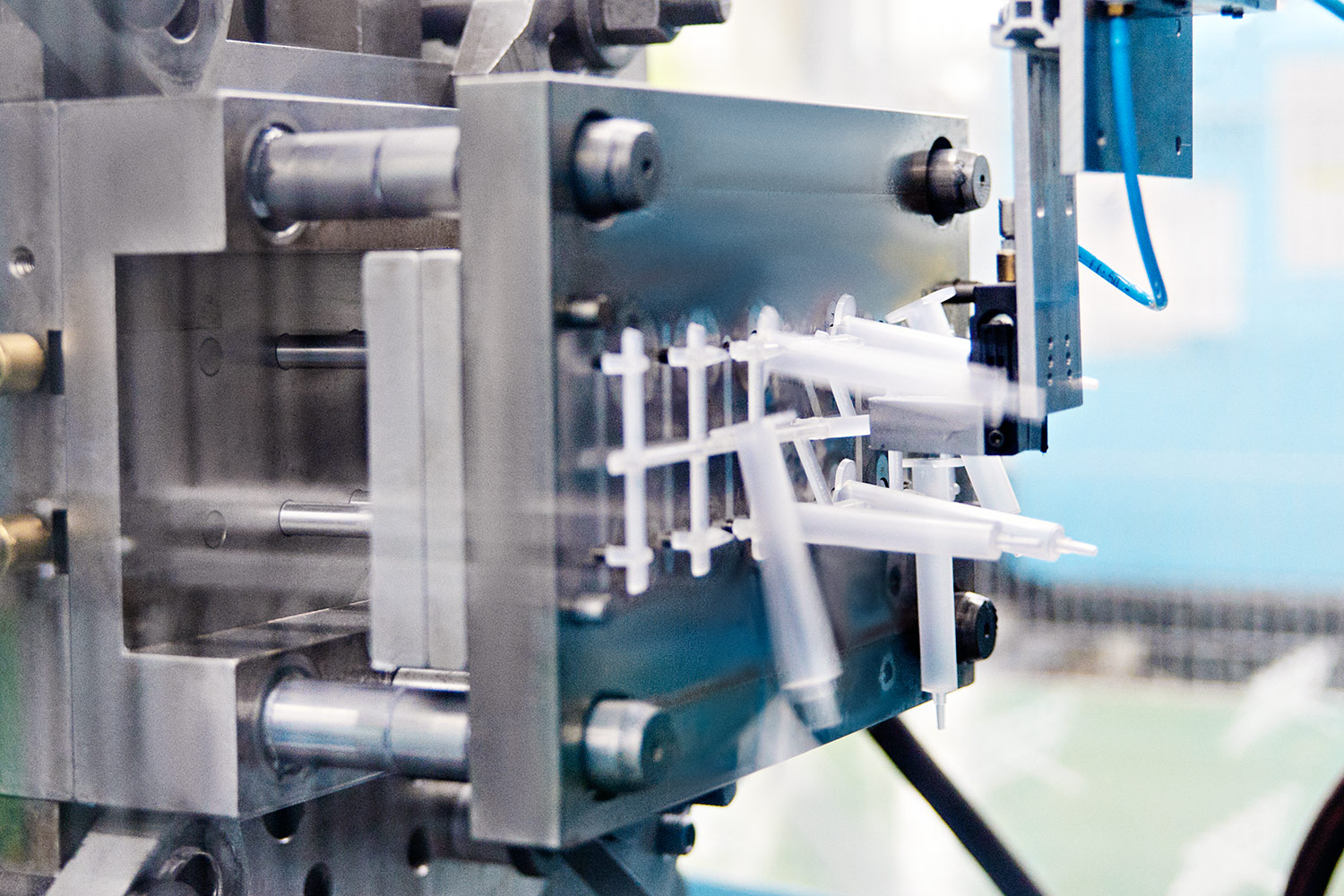

Schnell, effizient und hochwertig

Kunststoff-Spritzguss

für die Medizintechnik

Wir fertigen Ihre medizintechnischen Kunststoffteile und -baugruppen im Spritzgussverfahren – von der Kleinauflage bis zu millionenfachen Stückzahlen. Unser eigener Werkzeugbau garantiert eine schnelle Fehlerbehebung und Pflege Ihrer Werkzeuge. Die Produktion stellt Ihr Produkt wirtschaftlich, in konstant hochwertiger Qualität und mit einer besonders niedrigen Fehlerrate her.

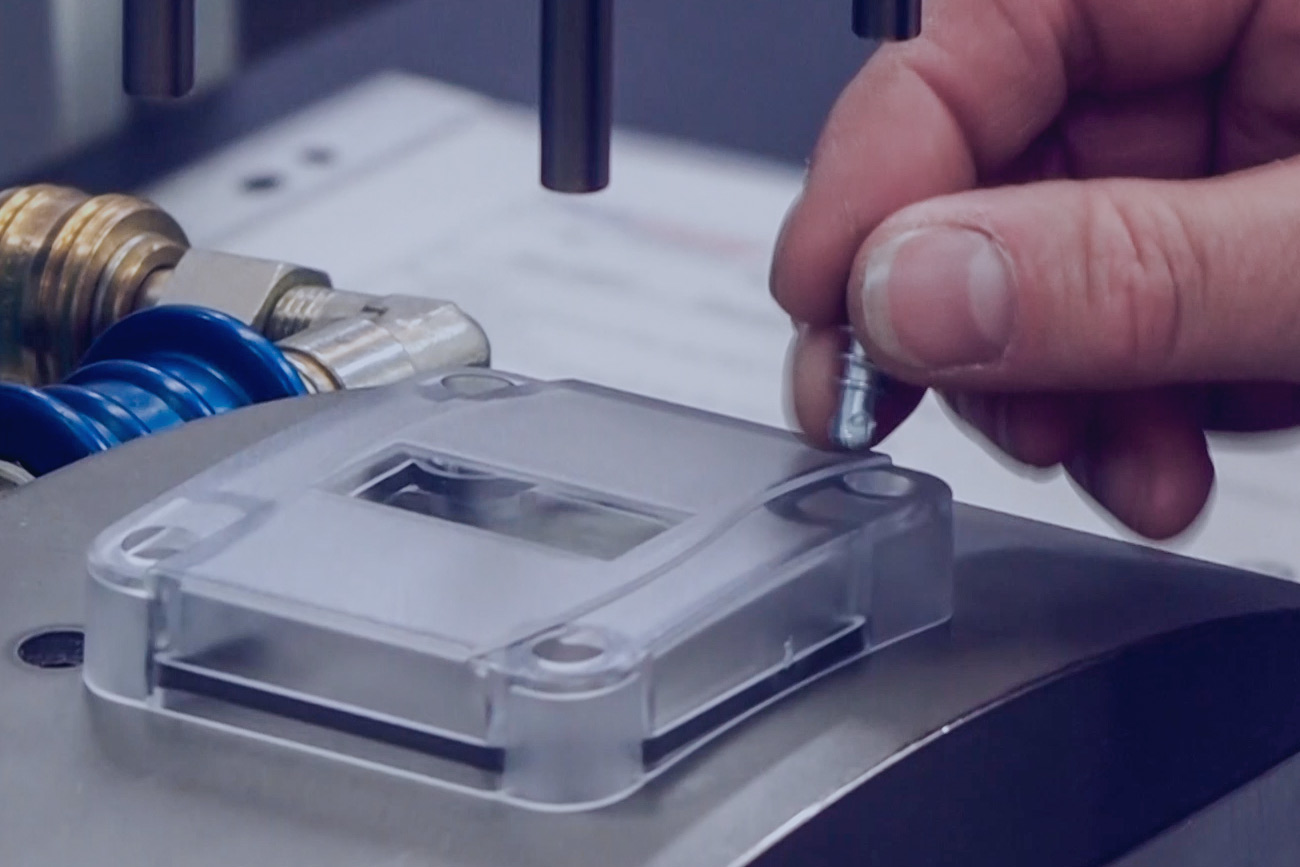

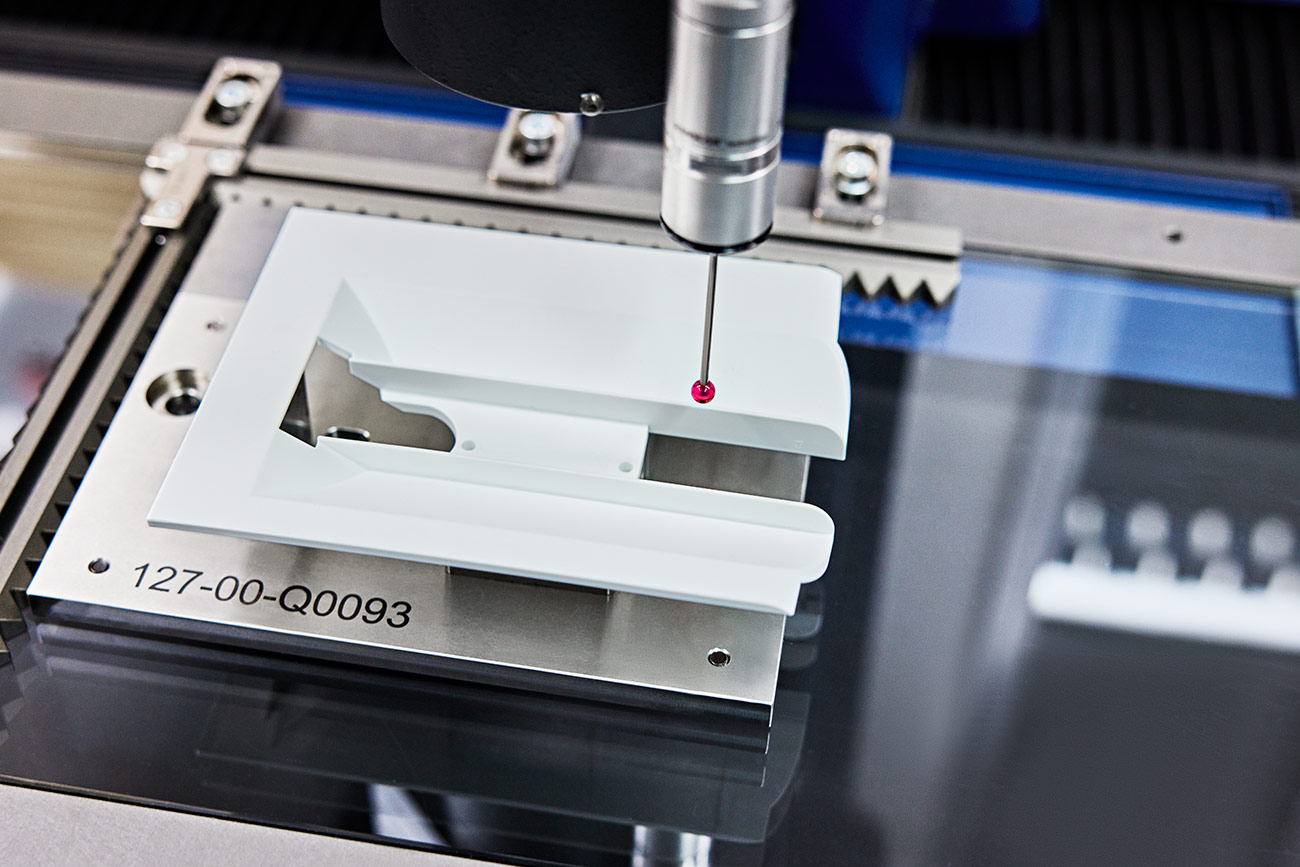

Qualitätsmanagement

Verlässlichkeit durch Qualität

Mit zertifizierten Prozessen, einem hauseigenen Prüfraum, hochwertigen Materialien und bewährten Lieferketten gewährleisten wir dauerhaft beste Qualität »Made in Germany«.

Werden Sie Teil des Polymold-Teams!

Aktuelle Stellenangebote

Wir sind immer auf der Suche nach qualifizierten und zuverlässigen Mitarbeitern. Wenn Sie Lust auf herausfordernde Aufgaben und Projekte haben, bewerben Sie sich bei uns.

Zur Verstärkung unseres Teams suchen wir aktuell

Polymold ist auch erfolgreicher IHK-Ausbildungsbetrieb und bietet interessante Ausbildungsangebote für Azubis.

Bestens aufgestellt für die Zukunft

Wir wachsen gemeinsam mit unseren Kunden

Als verlässlicher Partner verfügen wir stets über Möglichkeiten, unsere Produktionskapazitäten zu erweitern. Erhöhen sich die Stückzahlen Ihres Produkts, stellen wir die passenden Maschinen bereit. Ändern sich die Anforderungen Ihres Produkts, gleichen wir die Produktion entsprechend an. So sind wir bestens für die zukünftigen Anforderungen unserer Kunden aufgestellt.

Auch den dauerhaften Fortbestand unseres Unternehmens haben wir gesichert. Zum Jahreswechsel 2022 übernahm der neue Inhaber Jonathan Welz die Geschäftsführung bei Polymold.